Beijing Shougang Jitai An New Materials Co., Ltd. aims at the world's high-end and developed the first ultra-high temperature iron chromium aluminum pipe in China in June 2020, ending the history of wire free iron chromium aluminum materials in China and closely following the world-class level in the field of electric heating alloys. Ultra high temperature iron chromium aluminum tubes are produced using powder metallurgy methods to produce powder raw materials, followed by modern processes such as high-temperature hot isostatic pressing to produce steel billets. Subsequently, they are hot-rolled and precision processed to form electric heating alloy pipes with bright surfaces and precise dimensions.

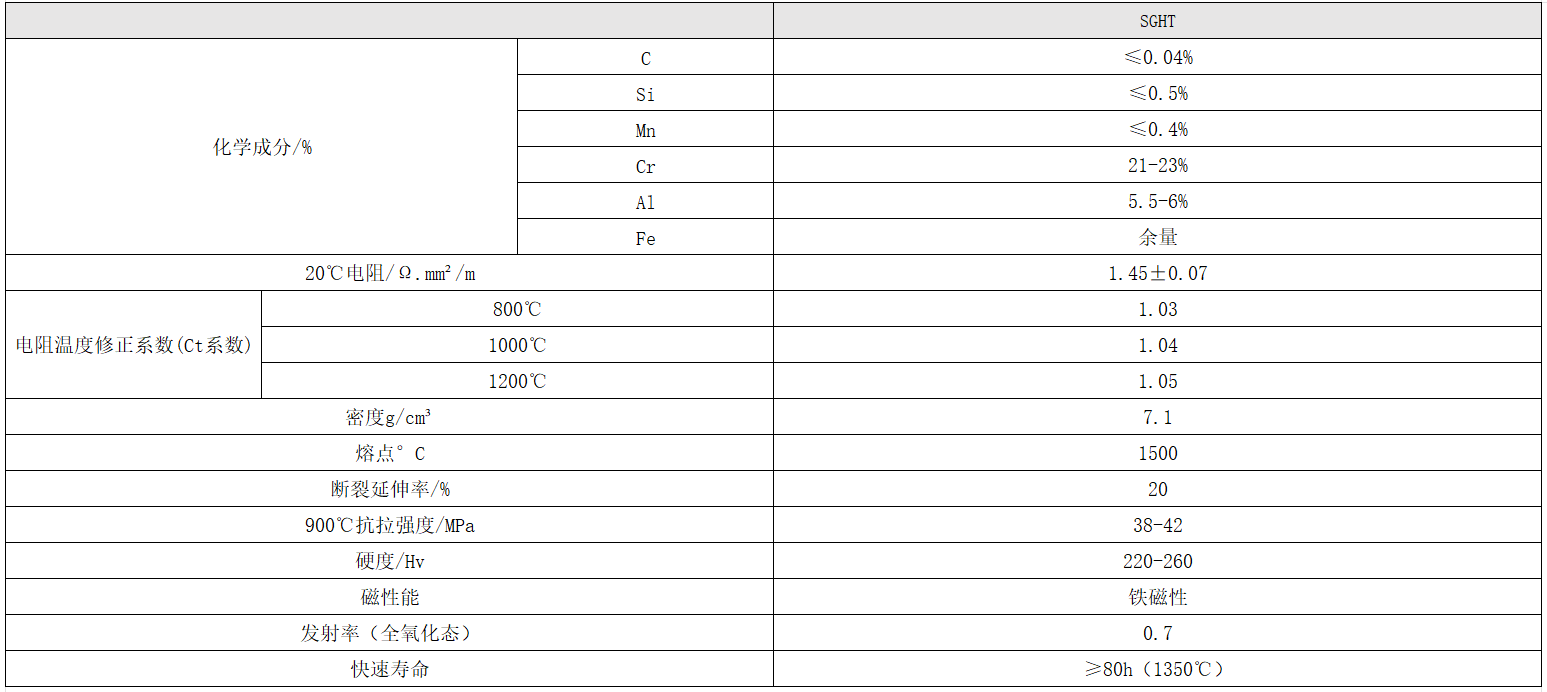

SGHT uses refined master alloys as raw materials and adopts powder metallurgy technology to manufacture alloy ingots, which are manufactured through special cold and hot processing and heat treatment processes. The product has strong antioxidant properties, good high-temperature corrosion resistance, small creep of electric heating elements, long high-temperature service life, and small resistance changes. Suitable for working environments with high temperature of 1425 ℃, high power density, corrosive atmosphere, carbon atmosphere, etc. Can be used in ceramic kilns, high-temperature heat treatment furnaces, laboratory furnaces, electronic industry furnaces, and diffusion furnaces.